Belting

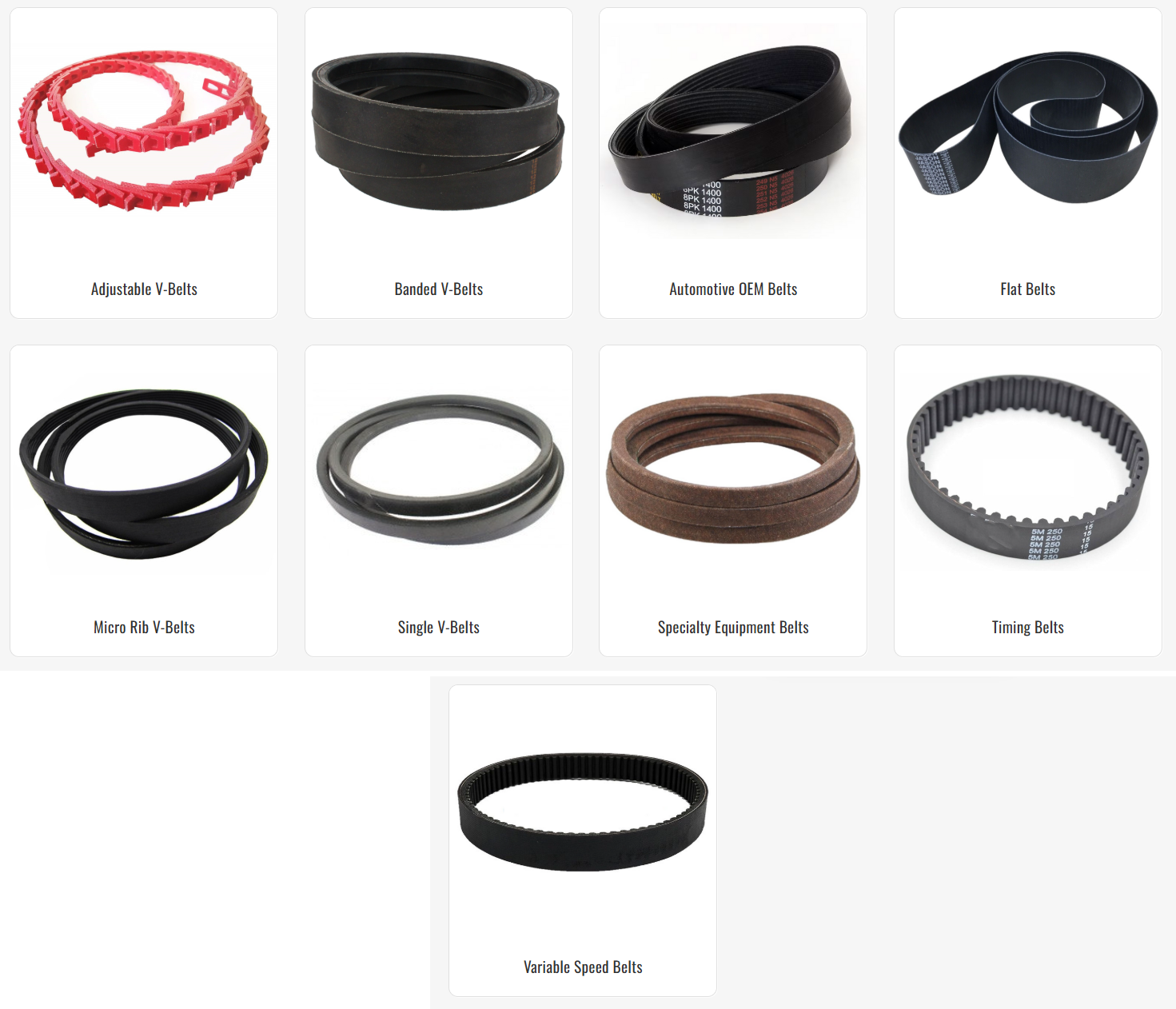

Power transmission belts, including timing belts, V-belts, and flat belts, are crucial parts that move mechanical power between shafts via positive engagement or friction. These vary depending on your industrial application, from aramid-reinforced heavy-duty belts made for high torque and shock loads to extremely flexible light-duty choices. For mechanical power transmission applications, Partscor offers a large selection of drive belts categorized by type, width, length, series, material, brand, and other factors. These belts are used to transmit mechanical power and are paired with sheaves. Both single-sided and double-sided belt options are available in both timing belts and V-belts.

The belt kinds that Partscor stocks and distributes are timing belts, flat belts, round belts, and V-belts. The tapered cross-sections of V-belts fit into the V-belt pulley grooves to convey high torque and lessen sliding brought on by under-tensioning. In pulleys with a 60-degree V groove, round belts are utilized. The teeth of timing belt pulleys and the exterior teeth of timing belts interlock.

Key Types of Transmission Belts

- V-Belts: The most popular kind of drive belt, they "wedge" into pulley grooves utilizing a trapezoidal form, increasing traction as the load increases.

- Synchronous (Timing) Belts: Toothed belts that offer a positive drive without slippage, which is crucial for applications that call for high-torque shock loads or exact timing.

- Flat Belts: Frequently seen in sawmills and fan drives because they are incredibly efficient (up to 99%) and can reach very high speeds with little vibration.

- Poly-V Belts: Also called serpentine belts, they are constructed to work well on sheaves with a smaller diameter and at high speeds. In addition to being wear-resistant, our Poly-V belts satisfy RMA requirements for heat resistance, oil resistance, and static conductivity.

This category contains no products.