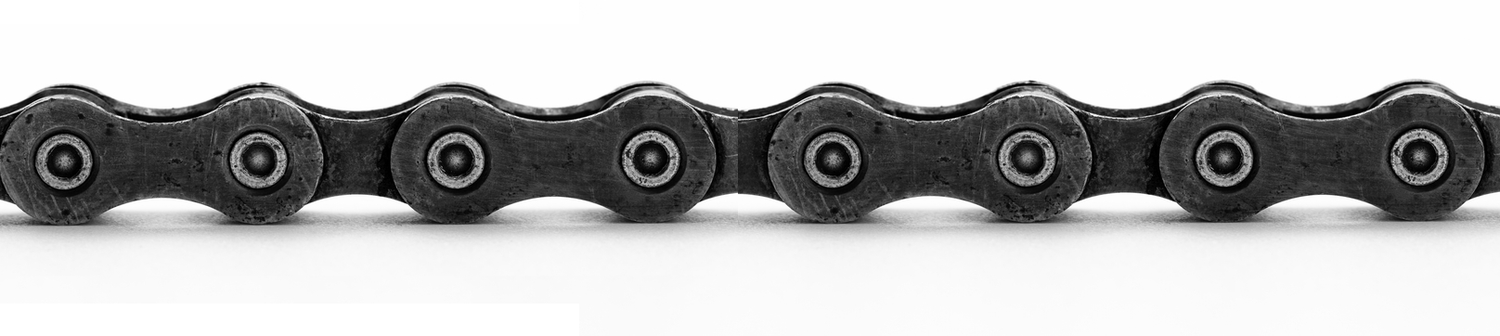

Drive Chain

A drive chain, or transmission chain, is a mechanical power transmission component that uses a series of connected links to transfer torque between sprockets. It is widely used in industrial machinery, motorcycles, and bicycles because it provides a constant speed ratio without the slippage common in belt drives. Because of their straightforward construction, roller chains are essential to conveyor systems and can support a wide variety of link and roller modifications. Lightweight chains for light-load, high-speed applications use small rollers. Roller chains with larger rollers and higher pitch values have a higher tensile strength, which allows them to support bigger loads. Attachment chain links attach to the chain or replace existing links to prolong or modify an attachment, whilst cotter pins and rivets enable multi-strand roller chain combinations.

Partscor provides ISO-British Standard (Metric) roller chain pitch sizes 03B through 085B and ANSI (Imperial) roller chain pitch sizes 25 through 240, along with related master (connecting) links and offset (half) links for mechanical power transmission systems. A revolving sprocket that drives the chain and connected rollers transfers mechanical power. A range of pitches, series, link types, and materials including carbon steel, stainless steel and nickel plated options are available in Partscor's inventory of roller chain and roller chain links.

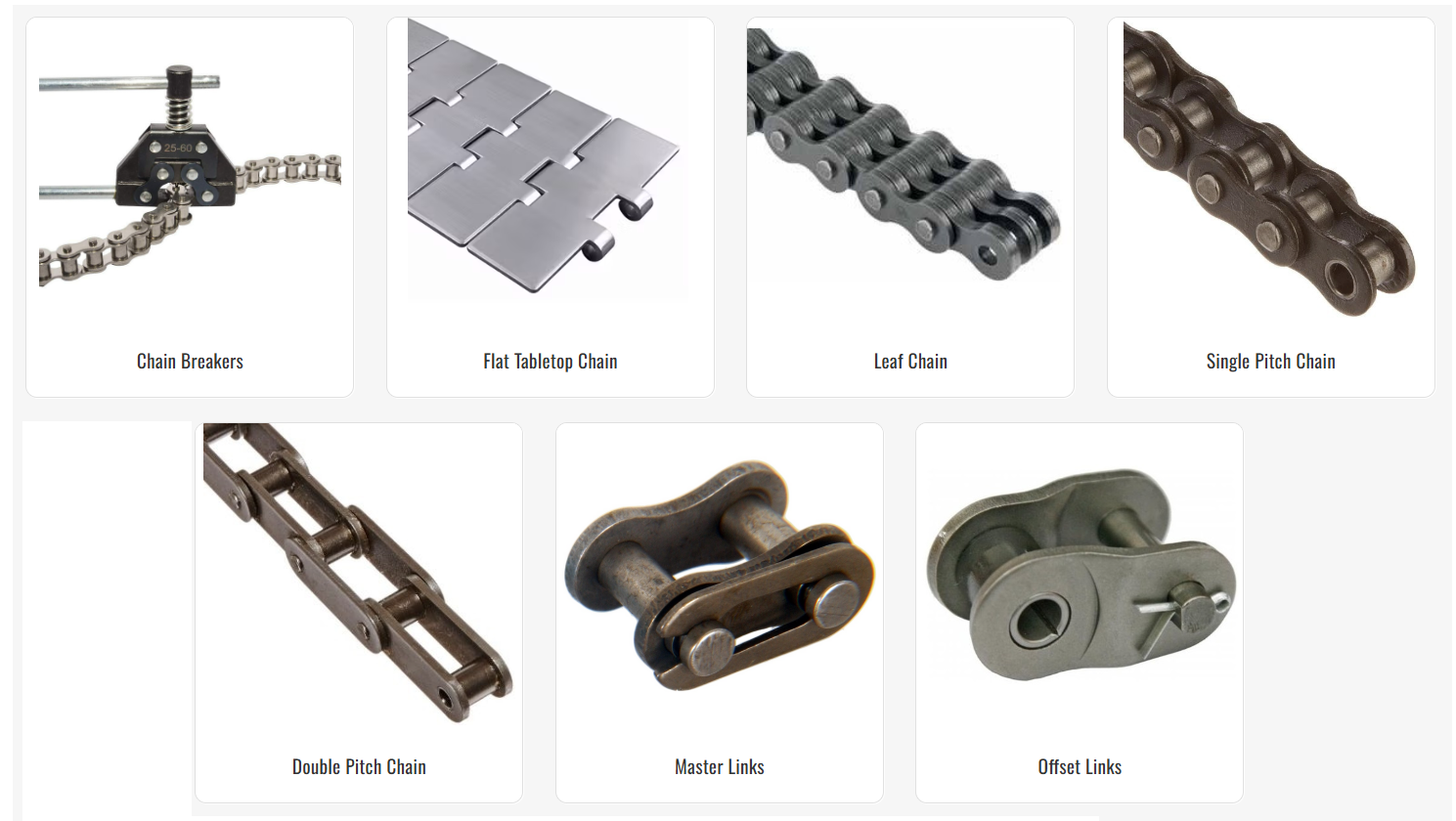

Drive Chain Types

- Single Strand: (Simplex) Roller Chains: The most common type of drive chain, designed with a single row of rollers to transmit power in industrial machinery. Ranging from #25 to #240 ANSI sizes (1/4" to 3" pitch)

- Double Strand (Duplex) Roller Chain: These consist of two parallel strands joined together. They are used when a drive requires more power and torque than a single strand can handle without significantly increasing the chain's pitch.

- Triplex Roller Chain: For even higher power requirements, triplex (triple-strand) chains provide a robust solution for heavy industrial loads.

- Double Pitch Roller Chain: Cost-effective alternative to standard roller chains, featuring a pitch length that is exactly twice as long while maintaining the same pin, roller, and plate dimensions.

- Silent Chain (Inverted Tooth): Designed for low-noise operation and reduced vibration compared to standard roller chains.

- Leaf Chain: Used primarily for material handling and lifting (like in forklifts) rather than continuous power transmission.

- Flat Top Conveyor Chain: Also known as tabletop conveyors, they utilize a continuous flat surface made of interlocking links to transport products smoothly.

This category contains no products.